I.C.E. Automotive Racing Engines has all the resources needed for developing peak performance from the engine of your choice. The three, key services are Flow Testing and Development, Dyno Testing and Machining.

Flow Testing and Development

Two basic aerodynamic factors intuitively influence airflow and efficiency of engine components and sub-assemblies in isolation, those being a bigger hole flows more air and a smoother hole flows even more.

At I.C.E. Automotive, we have the equipment to go beyond the above statement and prove the influences of other important factors including dynamic effects of induction systems and the effects of an air/fuel mixture inside an engine, as opposed to air alone, and the necessity to keep fuel suspended in an atomised form within a moving airstream.

Dyno Testing

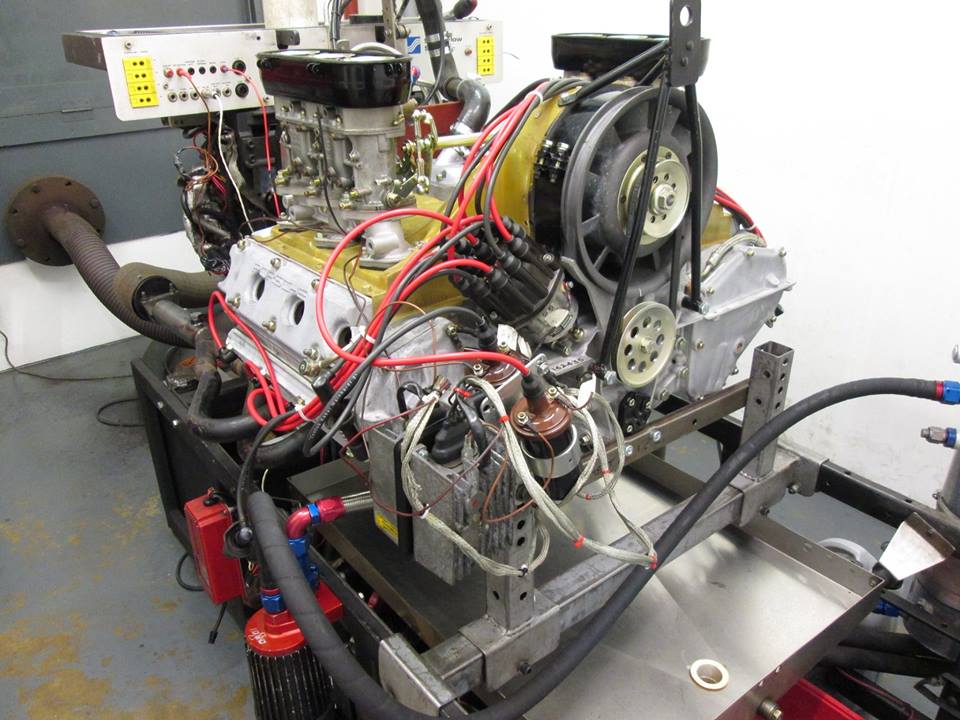

At a bare minimum, an engine builder will use a dynamometer to ensure critical mating surfaces are sealed properly, that rings are seated, that a camshaft is broken in and that an engine makes an appropriate power output.

At I.C.E. Autmotive, the Superflow 901 dyno is used as a tool to develop and refine engines via spark and fuel curve optimisation and the establishment of a baseline appropriate to its application, before an engine is installed in the car.

Interesting though they are, dyno figures are of negligible value in isolation. Though standardised correction factors lend them some comparability between dynos, the value at I.C.E. Automotive comes as much from the reference data contained within the extensive historic database as well as the interpretation of data generated, and its value and applicability to specific applications.

Machining

To satisfy customer requirements, control lead times and to ensure maintenance of quality standards, the in-house machine shop is equipped with sufficient machines to accommodate most engine-related tasks.